Granite Sandstone Block Squaring And Profiling Cutting Diamond Wire

Granite Sandstone Block Squaring And Profiling Cutting Diamond Wire

Description

| Type:: | Diamond Cutting Wire | Application: | Granite Stone Squaring And Profilling |

|---|---|---|---|

| Process: | Sintered | Bead Size: | 11mm |

| Bead Number: | 40 Beads | Quality: | Supreme |

| High Light: |

Block Squaring Cutting Diamond Wire, 11mm Cutting Diamond Wire, 11mm Diamond Wire Saw Rope |

||

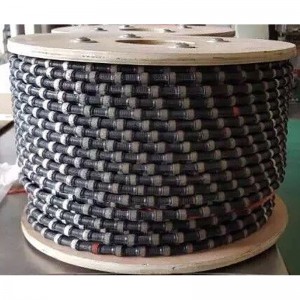

Granite Sandstone Block Squaring and Profilling Cutting Diamond Wire

1. Granite Squaring Cutting Diamond Wire Description

Diamond wires are cutting tools for rocks (marble, granite etc.), concrete and substitutes of saws in general. They are composed of an AISI 316 stainless steel cable over which are assembled diamond sintered pearls with 10 to 12 mm in diameter spaced 25 mm between each one. The wire is passed through coplanar holes previously made in the rock, and the tension imposed to the wire is made by a motor mounted on trails, coupled to the cutting system. The utilization of this slabbing technology has been expanded all over the world due to its advantages on the other techniques.

The steel wire works as a carrier for the beads and the rubber or plastic coating. For this we only use special high load open twisted wires, whose engineered structure ensures a perfect wire rotation with appropriate pre- twisting. The beads equipped with a diamond mantle segment carry out the actual cutting work. The base of these beads is a cobalt alloy,which has already proved its performance on our segments for diamond circular saws. This base has been modified in order to achieve optimum free cutting and long life characteristics for the wire saw. Embedded into this metal alloy is a diamond quality, which was chosen specifically for the use on diamond wire due to its extreme fractural strength and high quality crystal structure.

Our granite squaring and profiling sawing wire has 40 beads per meter, reforced by rubber and spring, 3 different bond to provide excellent supreme quality diamond wire for granite sand stone squaring and profiling.

2. Specificaiton of Granite Squaring and Profiling Diamond Wire

|

Code No. |

Specificaiton | Character |

|

VDW-GB/P01

|

11 x 40 beads | Soft bond for hardest granite stone |

|

VDW-GB/P02

|

11 x 40 beads | Medium bond for medium hard stone |

|

VDW-GB/P03

|

11 x 40 beads | Medium to hard bond to medium to soft stone |

3. Generally Cutting Data

| Code Number | Cutting Material |

Line Speed

|

Cutting Speed | Wire Life |

|

VDW-GB/P01

|

Hard granite | 25-30m/s | 6-10㎡/h | 7-10㎡/m |

|

VDW-GB/P02

|

Medium granite | 25-30m/s | 8-15㎡/h | 8-15㎡/m |

|

VDW-GB/P03

|

Soft granite | 25-30m/s | 12-20㎡/h | 10-20㎡/m |

4. Other Note

All diamond tipped cutting tools work best at a given surface feet per minute range, diamond wire operates best at a speed ranging between 4800 to 5500SFM. At this speed, material removal rate, cut time, power requirments and diamond bead wear are all optimized. Slower wire speeds are suggested at the beginning and end of cuts to reduce stress on the wire and wire sawing equipment and to allow for better control of the wire.