W8-G Tungsten Carbide 22mmx12mm 42CrMo Road Milling Bits

W8-G Tungsten Carbide 22mmx12mm 42CrMo Road Milling Bits

Description

| Type: | Asphalt Road Milling Bits | Other Name: | Wirtgen Road Cutting Teeth |

|---|---|---|---|

| Tip Material: | Tungsten Carbide | Shank Diameter: | 20mm |

| Tip Diameter: | 22mm X 12mm | Tip Shape: | Cap-Shaped |

| Application: | Asphalt Layer Removing | Machine Type: | Large Milling Machines |

| High Light: |

W8-G Road Milling Bits, 42CrMo 22mmx12mm Road Milling Bits, 22mmx12mm 42CrMo Road Milling Bits |

||

W8-G Asphalt Road Milling Bit Wirgten Asphalt Milling Machine Teeth

1. Road Milling Bits Description

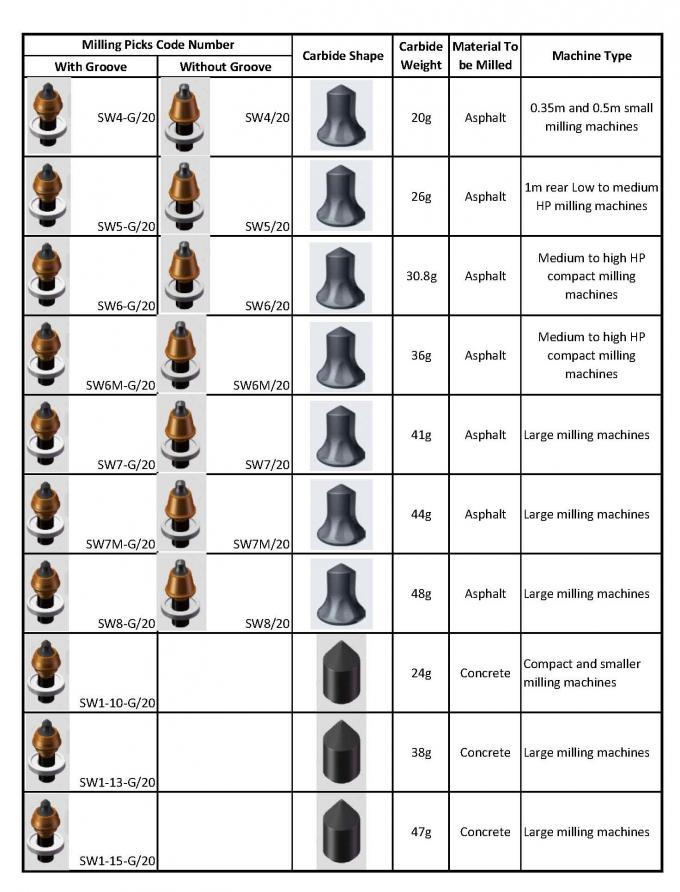

Road milling bits are also known as asphalt and concrete cutting bit, road planning picks, road milling machine cutter teeth, which are used as wear parts of road milling machine in road construction. Bit is installed in milling drum of milling machine and cut the road surface. The bits have two type, asphalt bits and concrete bits. Different bits are used on different aggragate and different milling machines.

Alloy steel Body, made by material ASTM4142 or 42CrMo,heat treatment with 40-44HRC hardness, has high toughness and wearable character. Tip with above 50 HRC hardness is made from low press sintered technology, carbide tip size and grade will be different to make sure a better milling performance and life.

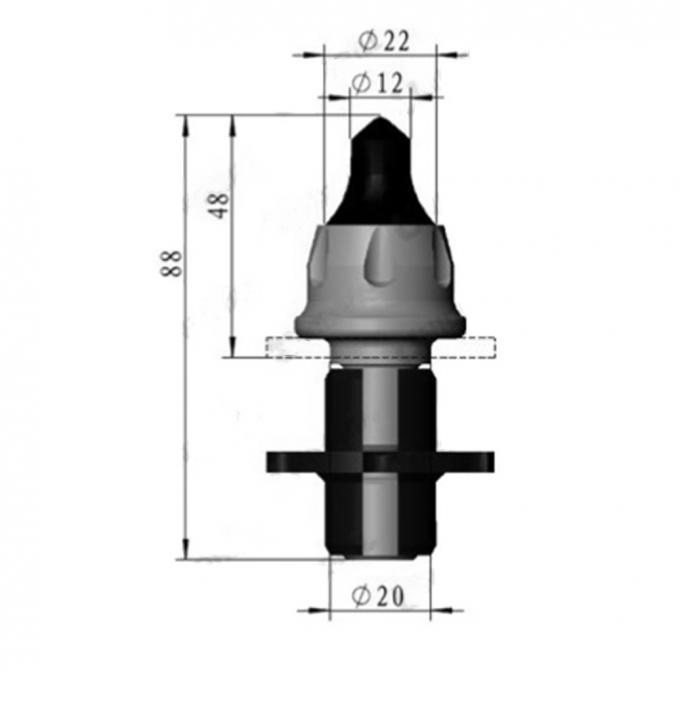

SW8-G/20 is cap-shaped carbide tip for removing asphalt layers, pick head without or with extractor groove as a dismantling aid. The shank diameter is 20mm, carbide tip diameter is 22mm x 12mm, high wear-resistant and strong breaking strength. Recommend for the large milling machines of Wirtgen, Dynapac, Cat, Kennametal or Sanvik.

2. Road Milling Picks Specification

| Type |

Meaning

|

| SW8/20 |

Compared to Wirtgen W8-G/20X2

|

| Appliciaton | Cap-shaped caride tip for removing asphalt layers. |

| Shank Diameter | Held in the toolholder bore with a shank diameter of 20mm |

| Carbide weight per pick |

48g

|

| Quantity per toolbox |

50 pieces

|

| Weight per toolbox |

17.5kg

|

3. Road Milling Picks List

4. Carbide Milling Tips Characters

- Be used for road milling, ground stabilizing, cutting asphalt and concrete

- The material of tooth body is 40CrMo or better, the machining process is forged

- Various design can be applied to most of cutting conditions

- Speedy creation of samples and prototypes

- High purity carbide tips are used for great strength

- Consistently high, pore-free tungsten carbide quality produced through an exact process resulting from years of experience

- Production equipment and processes specially developed to the utmost degree of perfection by experts in combining tungsten carbide and steel

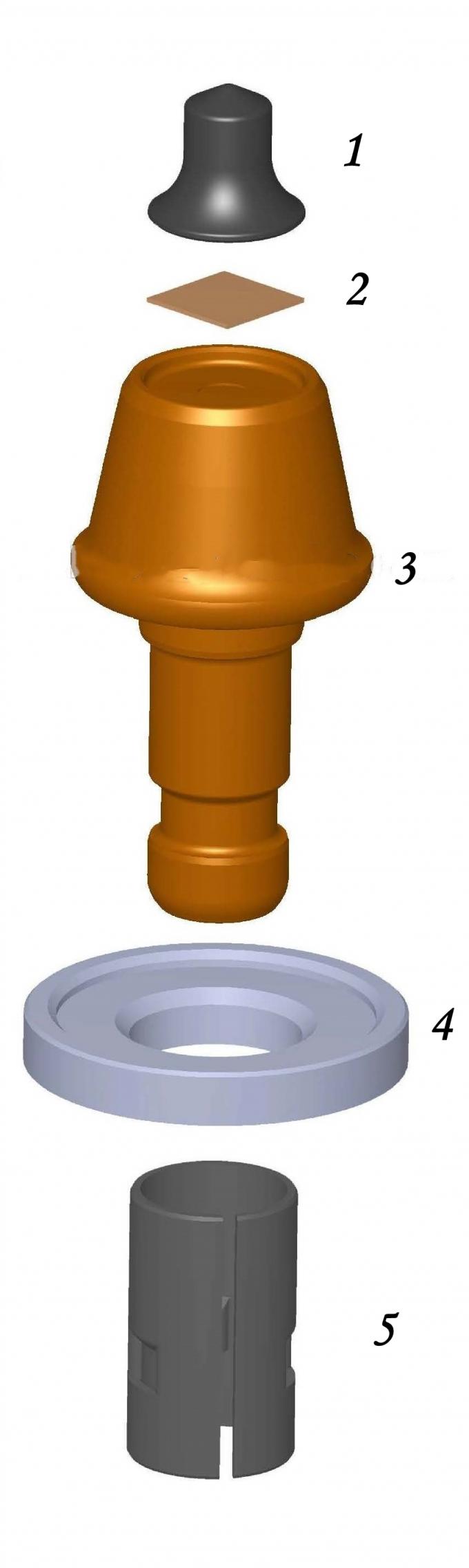

5. Carbide Picks Structure

1. Reasonable proportion of tungsten cobalt alloy to ensure the wear resistance and fracture resistance of the cutting pick.

2. Excellent flow solder to ensure weld strength.

3. Unique design of the body to improve the efficiency of retraction, to ensure smooth rotation, new heat treatment process to guarantee the wear resistance and fracture resistance of the cutter shank.

4. Thicken gasket design, ensure long life of the toolholder.

5. Thickening the sleeve, ensure moderate tension and clamping force, easy installation and removal.

6. Milling Machines Type

W8-G/20 can be used on Wirtgen large milling machines, such as the W1500, W1900, W195, W2000, W200, W200F, W207FI, W205, W200H, W215, W20H, W215, W210XP, W2100, W220, W2200, W250, W240CR, W380CR.